The high-quality UV-C reactor design

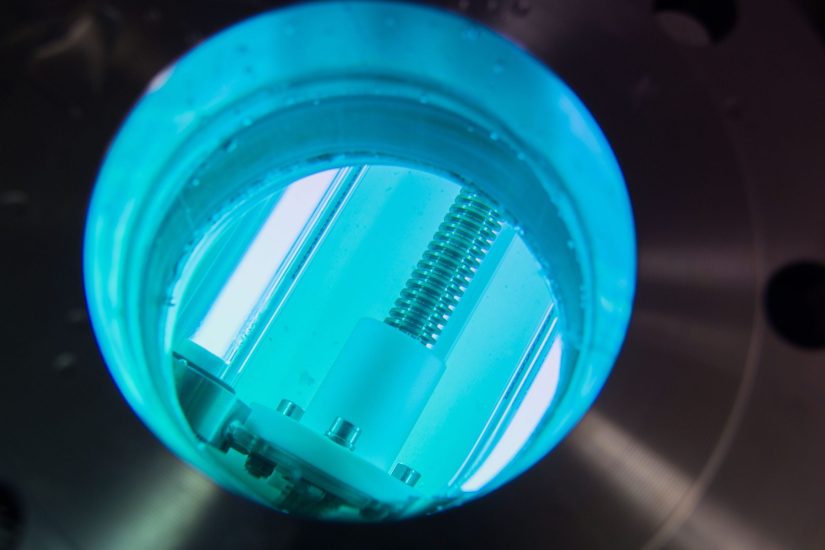

At first glance, a UV-C reactor looks quite simple. But this simple-looking design offers a lot in return. The water enters the UV-C reactor on one side and comes out the other side. It seems simple, but there is a lot of attention paid and ground won in the details. In this tube, also called ‘the chamber’, there are powerful UV-C lamps that disinfect the water during the draft. We calculate exactly how that water runs past it using computer models.

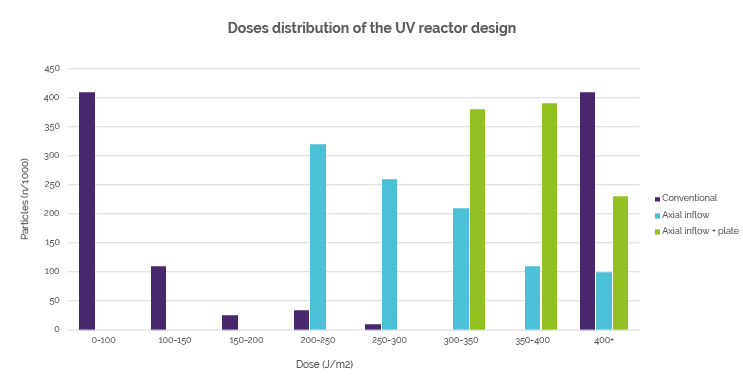

When disinfecting liquids, only one thing counts for us: certainty. There should not be too much UV-C radiation because that costs unnecessary energy. But not too little either, because it must remain harmful to the micro-organisms. That is why we look for the ideal distribution of UV-C light. Ideally, each part of the liquid flow receives the same dose of UV-C light. This is difficult in practice because liquids have a preference for a certain flow direction. Two flows can be created in some reactors. A flow that chooses the fastest path and therefore doesn’t absorb enough UV-C light, and another stream that chooses a longer path and therefore absorbs an unnecessarily high dose of UV-C light. We have devised smart solutions for this in our innovative systems.